2026-02-03

Aluminium plain sheet is a flat rolled product supplied without decorative coating or printing. It is commonly chosen when you need predictable forming, corrosion resistance, or a clean base material for later finishing. For bulk procurement, the most frequent confusion comes from surface terms, alloy temper selection, and how tolerances impact yield and downstream processing.

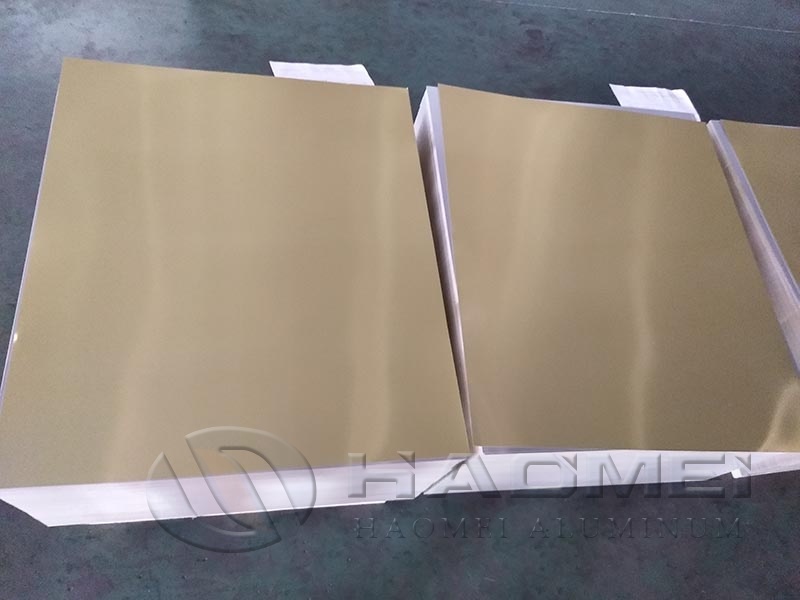

A plain sheet usually refers to mill produced flat stock with a standard industrial surface, often called mill finish. It is not the same as anodized, painted, embossed, or printed material, although it can be used as the starting substrate for those processes. Surface appearance may include light rolling marks, and reflectivity can vary by alloy and mill practice.

When specifying, use objective parameters rather than subjective words like bright or smooth. The core items are alloy, temper, thickness, width, length, and tolerance class, plus any surface protection such as interleaving paper or PVC film.

Aluminum alloys are standardized by series, and selection should match the dominant requirement, such as forming, strength, or corrosion resistance.

| Alloy series | Common alloys | Strength level | Formability | Corrosion resistance | Typical industrial uses |

|---|---|---|---|---|---|

| 1xxx | 1050, 1060, 1070 | Low | Excellent | Excellent | Chemical equipment, reflectors, general fabrication |

| 3xxx | 3003, 3105 | Low to medium | Very good | Very good | Roofing, cladding, heat exchanger fins |

| 5xxx | 5052, 5083 | Medium to high | Good | Excellent, especially marine | Tanks, shipbuilding, pressure related fabrication |

| 6xxx | 6061, 6082 | Medium to high | Fair to good | Good | Structural parts, machining, frames |

If you are comparing 3003 vs 5052, the typical tradeoff is that 5052 provides higher strength and better marine corrosion performance, while 3003 often offers easier forming at lower cost. For structural machining, 6061 is widely used, but it can be less forgiving in tight radius forming than softer 1xxx or 3xxx options.

Temper indicates how the metal was processed to achieve its mechanical properties. Common tempers include:

For bulk orders, temper affects not only forming but also flatness and residual stress. If parts will be laser cut and then bent, discuss the balance between strength and bendability early, because a higher temper can increase springback and cracking risk on tight bends.

Yield loss often comes from overlooked tolerances. Thickness tolerance impacts weight calculations and cost per part. Flatness and waviness affect CNC nesting, laser focus stability, and cosmetic quality after finishing.

Ask for the applicable standard and tolerance class used by the mill, then align it with your process window. If your operation is sensitive to flatness, request inspection data such as flatness measurement method and acceptance criteria.

Plain material can still be damaged by handling, especially on large bundles. Consider:

If you will anodize later, confirm that the film adhesive is compatible with your cleaning line to avoid residue that can cause staining.

No. Mill finish is a general term, not a single cosmetic grade. Rolling marks, gloss, and color tone can vary by alloy, rolling schedule, and lubrication. If appearance is important, request reference samples, define acceptable surface class, and specify whether one side is designated as the A side.

Food contact compliance depends on local regulations, alloy, surface condition, and the final use environment. When compliance is required, specify the target regulation or market requirement and request documentation from the supplier. Do not assume that a common alloy is automatically certified for a specific food contact application.

Typical documentation includes a mill test certificate showing chemistry and mechanical properties, plus dimensional inspection records if tight tolerances are needed. If you require consistent incoming quality, align on inspection sampling, test methods, and traceability by heat and bundle.

Providing complete information reduces back and forth and improves price accuracy.

| Item to specify | Example | Why it matters |

|---|---|---|

| Alloy and temper | 5052 H32 | Determines strength, corrosion behavior, and forming |

| Thickness, width, length | 2.0 mm x 1250 mm x 2500 mm | Impacts yield, nesting, and freight |

| Tolerances | Standard or tight | Impacts process capability and cost |

| Surface requirement | Mill finish, one side protected | Controls cosmetic acceptance and handling |

| Quantity and lot strategy | Annual volume, per shipment | Enables scheduling and price stability |

| Packaging | seaworthy, edge protectors | Reduces transit damage and claims |

If your production uses both general purpose and higher performance plate like 5083, it can help to standardize fewer alloys and tempers to simplify inventory, provided the engineering requirements allow it.

If your application needs a standardized substrate for downstream finishing, consider sourcing the base material as Plain Aluminum to keep surface and mechanical properties consistent across batches. For projects that later require forming and then coating, a stable incoming surface on mill finish aluminum can reduce rework caused by scratches and oil stains.

For large lots, a quick incoming inspection can prevent production disruptions.

For high volume programs, align on a nonconformance process with photos, sampling rules, and claim timelines before shipments start. This reduces disputes and keeps supply stable.

Tags: aluminium plain sheet | mill finish aluminum sheet |

Original Source: http://alclosuresheet.com/a/aluminium-plain-sheet.html

+86-15978414719

+86-15978414719

sale@alumhm.com