2026-02-09

Painted aluminum sheet shows up often in questions because it looks simple but behaves differently depending on the coating system, alloy, and how you fabricate it. Below are 5 high intent questions that have been trending recently on Quora style threads and search results, answered in practical terms for anyone comparing options for signs, panels, enclosures, and building components.

A common question is whether PVDF is worth the premium or if polyester is fine. The most useful way to decide is to start from the exposure.

PVDF (often 70 percent PVDF resin systems) is chosen when you need long term color and gloss stability in sun, heat, and humidity. It is widely specified for exterior architectural surfaces because it resists chalking and fading better over time.

Polyester is typically used when the job is interior, short to medium outdoor life, or when cost and color variety matter more than maximum weathering performance.

What many people miss is that performance is not only the resin name. The actual outdoor behavior depends on film thickness, primer system, pigment quality, curing, and substrate pretreatment. If two suppliers both say PVDF, ask for the coating specification, dry film thickness, and the test standard they claim.

If you are comparing options, it helps to look at product positioning pages like Painted aluminum to see which coating families are offered for your application, then confirm the coating spec in writing on the purchase order.

This question comes up a lot after someone receives material that looks perfect, then gets hairline scratches during handling, bending, or assembly.

Painted surfaces are polymer films. Even tough coatings can scratch if:

The protective film is removed too early.

Sheets slide against each other without interleaving.

You bend with a dirty die or worn rollers.

Fasteners or chips contact the face side.

Ways to reduce scratches in real production:

Keep the PVC or PE protective film on during cutting and forming, removing it only at final inspection.

Use clean gloves, clean tables, and soft separators.

Confirm the coating is meant for forming. Some coatings are optimized for hardness, others for flexibility.

For bending, specify the bend direction if relevant. Some coil coating systems and surface textures show micro marks more in one direction.

If you need high mar resistance, ask about textured finishes, harder clear coats, or thicker topcoats. Do not assume glossy equals durable. Some matte or textured options hide handling marks better.

People often ask for a single number. The more accurate answer depends on environment and coating type.

In high UV and heat regions, coatings age faster.

In coastal or industrial zones, salt and pollutants accelerate corrosion risk at cut edges and fastener points.

Instead of asking only about years, ask for:

The coating standard used (common references include AAMA style performance frameworks in North America).

Expected color change and gloss retention limits under a defined exposure.

Whether the system includes a suitable pretreatment and primer for adhesion and corrosion resistance.

A practical rule: if your project is exterior and appearance is critical for the long run, PVDF systems are usually selected. If the surface is shaded, vertical, or has short replacement cycles, polyester may be acceptable.

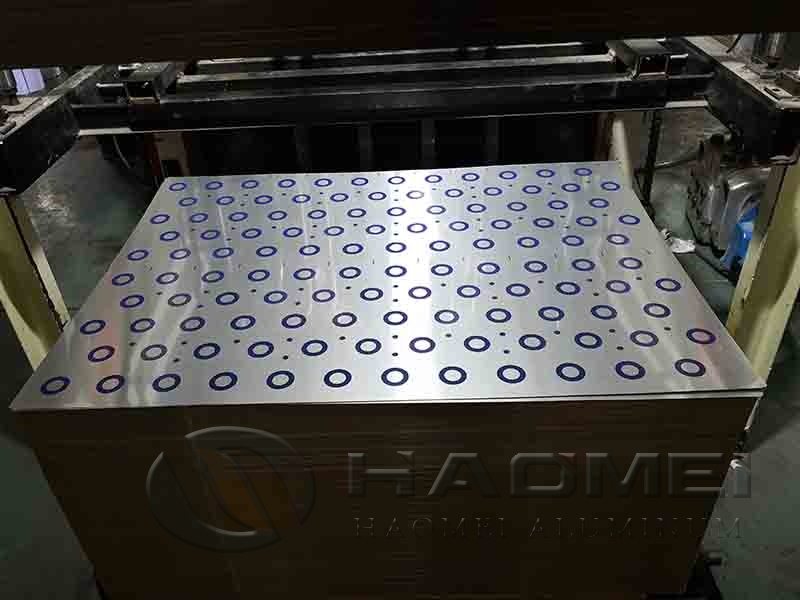

This is trending because makers and fabricators want painted material but also want clean fabrication.

Bending: Usually feasible if the coating is formable and the bend radius is not too tight. Ask the supplier for minimum bend radius guidance. Tighter bends increase risk of micro cracking, especially in cold temperatures.

Laser cutting: Possible, but edge quality and discoloration depend on parameters and coating chemistry. You may see burning or soot on the painted side. Masking film can help, but it can also melt if settings are wrong.

Welding: Welding will burn the coating near the weld zone and produce fumes. For welded assemblies, it is often better to weld bare material and paint after, or plan for a post weld refinish area.

Best practice: define the fabrication method first, then match the coating and film thickness to it. If the part must be welded, factory painted stock may not be the right approach unless the weld area is designed to be hidden or refinished.

Color mismatch is one of the most searched pain points. The cause is rarely a single factor.

Common reasons painted aluminum sheet varies:

Different production batches with slightly different pigment lots.

Viewing differences under LED, daylight, and warm indoor light.

Gloss level variation due to cure conditions or film thickness.

Metamerism, where two samples match in one light source but not another.

To improve your odds of consistency:

Provide a standard color reference such as a RAL code or a physical chip, and confirm the agreed tolerance.

Specify gloss target and tolerance (for example, 30 plus or minus a certain value at 60 degrees).

Request material from the same production batch when appearance continuity matters.

Ask for a pre production approval sample and keep it as a control sample.

If your design uses graphics or woodgrain effects, you may also want to compare with decorative solutions, but confirm whether the product is coil coated, digitally printed, or laminated because durability and scratch behavior differ.

| Question to ask | Why it matters | What a good answer includes |

|---|---|---|

| What coating system is it, PVDF or polyester? | Sets expectations for outdoor durability | Resin type, topcoat and primer, recommended exposure |

| What is the total dry film thickness? | Affects weathering, flexibility, and mar resistance | Primer and topcoat thickness ranges |

| What pretreatment is used? | Impacts adhesion and corrosion resistance | Chromate free or other pretreatment type, test references |

| Is there protective film, and what type? | Reduces transit and fabrication scratches | Film type, adhesion level, removal notes |

| What bend radius is recommended? | Prevents coating cracks | Minimum inside radius guidance for your thickness |

Even when the face finish is excellent, outdoor complaints often start at cut edges, drilled holes, and fastener points. These areas may need sealant, edge treatment, isolating washers, or design features that reduce water retention. If you share the environment and installation style, a supplier can recommend the best combination of coating system and edge protection.

Tags: painted aluminum sheet | coil coated aluminum | PVDF painted aluminum |

Original Source: http://alclosuresheet.com/a/painted-aluminum-sheet.html

+86-15978414719

+86-15978414719

sale@alumhm.com