2025-10-21

The aluminium sheet for food packaging with its unique physical properties and processing advantages, has gradually emerged from numerous packaging materials. It has demonstrated irreplaceable value in bottle cap packaging, particularly in the application of anti-theft caps.

When discussing the use of aluminum sheet in packaging, many people first think of its lightweight and portable nature. With the same protective performance, aluminum sheet weighs only one-third of steel, significantly reducing logistics and transportation costs. This is a key reason for its widespread use in packaging such as beverage cans and food boxes.

But aluminum sheet's advantages extend far beyond this: it possesses excellent barrier properties, effectively shielding against oxygen, moisture, and light, preventing oxidation and deterioration of the contents. This is crucial for packaging food and pharmaceuticals that require long-term storage.

Furthermore, aluminum sheet is highly ductile and can be processed into a variety of complex shapes through processes such as stamping and stretching to meet diverse packaging design requirements. Crucially, aluminum sheet is highly recyclable, aligning with the current trend toward "green packaging," reducing resource waste and lowering companies' environmental costs. Within the bottle cap packaging segment, anti-theft caps place the most stringent demands on materials.

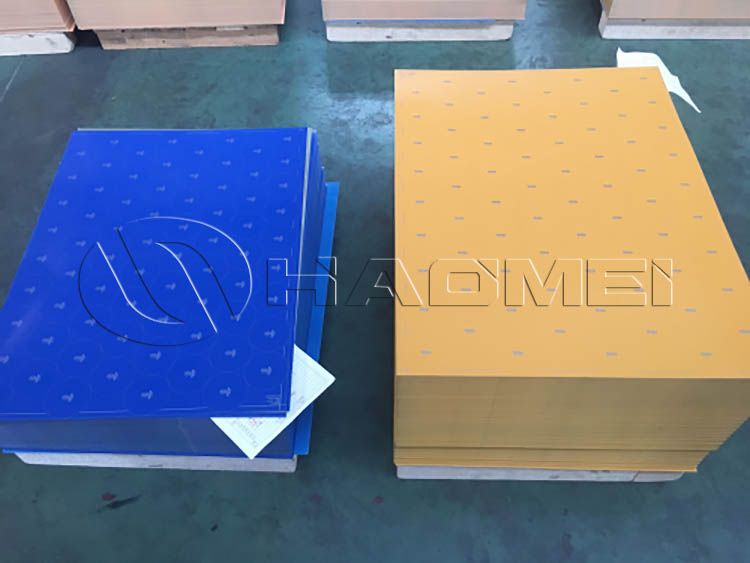

They must not only provide basic sealing and hygienic properties, but also be designed to achieve a "one-time opening"—meaning they cannot be restored to their original shape after opening, thus ensuring the product has not been tampered with. Alu sheet for pp covers perfectly meets these requirements, making it the core material for anti-theft caps.

The core design of the anti-theft cap is the "anti-theft ring," a ring-shaped structure attached to the bottom of the cap. When opening, the ring must be twisted to separate from the main body of the cap, and once separated, it cannot be reattached. This design places extremely high demands on the material's ductility and toughness.If the material is too brittle, the ring will easily break during transportation; if the material is too soft, the ring will not separate smoothly during opening. Aluminum sheet's ductility is perfectly within the "golden range"—it can precisely form the anti-theft ring through the stamping process while maintaining stable fracture resistance during opening, ensuring the "one-time opening, permanent failure" design.

In addition, aluminum sheet offers moderate strength, resisting crushing and collisions during transportation, preventing the anti-theft ring from accidentally falling off, while also allowing consumers to open it easily without tools. For example, in liquor anti-theft caps, the aluminum anti-theft ring can withstand certain external impacts, while allowing consumers to open the bottle with a simple twist, achieving a balance between safety and convenience.

With evolving consumer demands, anti-theft caps are no longer solely tamper-resistant; they also need to offer added value such as anti-counterfeiting and easy recycling. The characteristics of aluminum sheet facilitate these functional upgrades.

For anti-counterfeiting purposes, aluminum sheet surfaces can be finely printed, hot-stamped, or laser-engraved. For example, pharmaceutical anti-theft caps can be printed with a unique security code or texture, allowing consumers to verify the product's authenticity by scanning the code.

Furthermore, the metallic texture of aluminum sheet enhances the packaging's premium character. For example, in high-end cosmetics anti-theft caps, aluminum sheet, combined with a frosted or polished finish, enhances the product's visual impact and increases brand premium.

Aluminum sheet has an environmentally friendly recycling rate of over 95%, significantly higher than plastic. PP covers made from aluminum sheet can be recycled with other metal waste after the product is consumed. After melting, they can be reprocessed into new aluminum sheet, achieving a "recycling" process that aligns with current trends in environmentally friendly packaging.

Tags: bottle cap material |

Original Source: http://alclosuresheet.com/a/alu-sheet-for-pp-covers.html

Product

Alloy

Application

+86-15978414719

+86-15978414719

sale@alumhm.com