2025-12-10

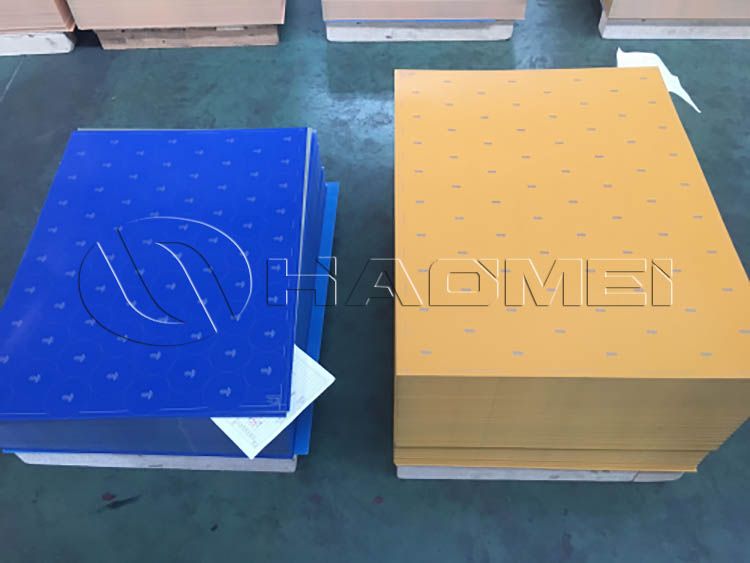

The manufacturing of aluminum bottle caps begins with material selection. Not all aluminum sheets are suitable; they must meet food contact safety standards while possessing excellent processing performance, sealing properties, and corrosion resistance.

As an aluminum-manganese alloy, 8011 aluminum contains approximately 1% manganese, a composition that gives it numerous advantages. Firstly, it boasts excellent processing performance. The manufacturing process of aluminum bottle caps involves multiple stamping and stretching processes. 8011's high elongation and good plasticity allow it to easily handle complex forming processes. Even after repeated processing, it is not prone to cracking or breakage, ensuring the dimensional stability of the bottle cap.

Secondly, it exhibits extremely strong corrosion resistance. Beverages inevitably contain acidic or alkaline substances, and 8011 effectively resists the corrosive effects of these substances, preventing the aluminum from oxidizing and rusting, which could affect the quality of the beverage.

More importantly, 8011 meets the stringent standards for food contact aluminum materials. It is non-toxic, odorless, and will not chemically react with beverages, safeguarding drinking safety from the source. Currently, most wine bottle caps on the market use 8011 aluminum alloy as their raw material.

The most prominent characteristics of 1060 aluminum are its high purity and excellent surface gloss. After polishing, it exhibits a delicate and smooth texture, making it ideal for bottle caps requiring intricate printing, such as those for health supplements and high-end beverages.

Furthermore, 1060 has excellent thermal and electrical conductivity, allowing for rapid and even heating during subsequent drying and printing processes, thus improving processing efficiency.

However, due to the relatively low strength of pure aluminum, 1060 alone is insufficient to withstand significant external forces when manufacturing bottle caps. Therefore, it is typically used in combination with plastics or for lightweight bottle caps where strength requirements are less stringent.

Workers cut aluminum coils into strips of appropriate width according to the cap dimensions. The strips are then cleaned to remove oil, oxide films, and other impurities. This step is crucial; impurities on the aluminum strip surface can affect subsequent stamping and coating adhesion, and may even contaminate the beverage.

After cleaning, the aluminum strip undergoes annealing. Through heating and cooling, the internal stress generated during rolling is eliminated, further enhancing its plasticity and preparing it for subsequent stamping processes.

The pre-treated aluminum strip is fed into a high-speed stamping press, the most crucial step in the manufacturing process. The press uses a special die to stamp the aluminum strip in a single pass, instantly completing both the "material cutting" and "forming" actions.

This process demands extremely high precision in the die and high stamping speed. The die error must be controlled within 0.01 mm, and the stamping speed can reach hundreds or even thousands of times per minute, ensuring that the dimensions of each bottle cap blank are completely consistent.

The stamped bottle cap blanks may have burrs or uneven dimensions in the skirt area, requiring trimming. A specialized trimming machine removes excess skirt material, ensuring a uniform skirt height and smooth edges.

Next, the bottle caps enter a shaping machine. Through the extrusion of an internal mold, key dimensions such as the cap's diameter and height are calibrated to ensure a precise fit between each cap and the bottle opening, laying the foundation for a tight seal.

Surface treatment consists of two parts: internal coating and external printing. The internal coating is crucial, requiring a food-grade epoxy resin coating to be sprayed onto the inside of the cap. This coating further isolates the aluminum from the beverage while enhancing the cap's seal and preventing leakage. The coating material must meet national food-grade standards, and the coating thickness must be uniform, typically controlled between 0.01-0.02 mm.

External printing enhances the bottle cap's appearance. Using screen printing or offset printing techniques, the brand logo, product information, and attractive designs are printed onto the cap's surface. If 1060 h12 aluminum alloy is used, its excellent surface gloss allows for clearer printing and more vibrant colors. After printing, a drying process is performed to ensure the ink adheres firmly and does not easily peel off.

To make it easier for consumers to open the bottle cap, an embossing process is applied to the edge of the cap to increase friction between the hand and the cap. The depth and spacing of the embossing are strictly regulated to ensure ease of opening without compromising the strength of the edge. Finally, and most importantly, is the quality inspection. Inspectors will use specialized equipment to comprehensively test the cap's dimensions, seal, coating thickness, printing quality, and other aspects.

Original Source: http://alclosuresheet.com/a/how-are-aluminum-bottle-caps-made.html

Product

Alloy

Application

+86-15978414719

+86-15978414719

sale@alumhm.com