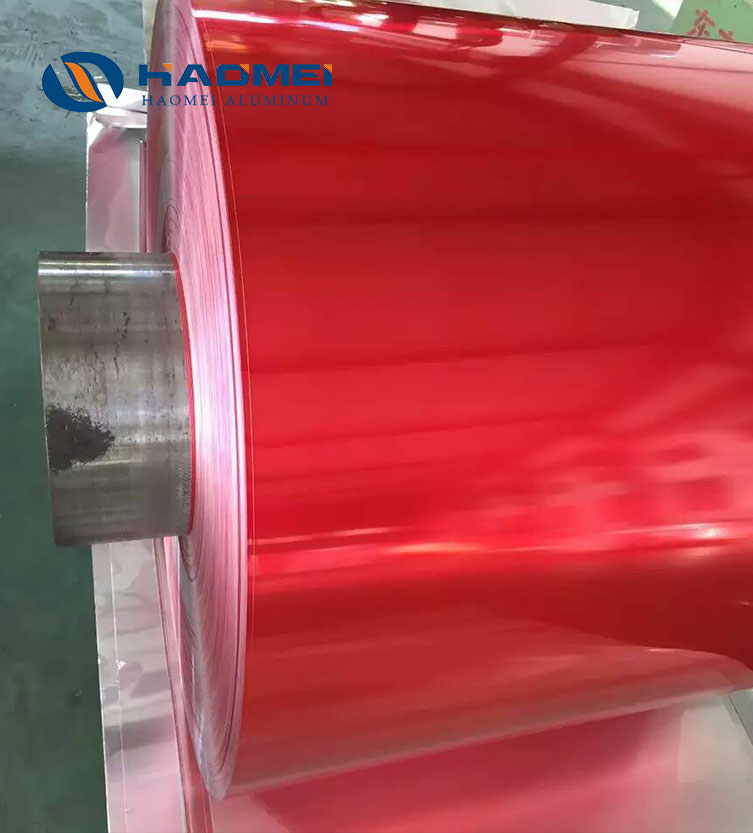

3105 aluminum foil sheet are widely used for making bottle caps of wine, beverage,medicines,especially the carbonated beverages due to high strength. Different surface treatments are available. Learn more.

Alloy3105

TemperH14,H24,H16 ,H26,H18

Applicationfor carbonated beverage

CERTIFICATE

3105 aluminum belongs to 3xxx aluminum-manganese alloy. It has good anti-rust properties and good deep drawing effect. The strength, elongation and processing performance of the 3105 alloy meet the requirements of the automated high-intensity bottle cap production process, and no creases or cracks will appear during processing.

Moreover, the 3105 bottle cap material has a flat shape, no roller marks, and no oil spots, which is convenient for later printing and makes the pattern very clear. When bottle caps are used to enclose carbonated beverages, 3105 alloy must be used due to enough strength.

Compared with traditional plastic bottle caps, aluminum alloy bottle cap materials have good sealing properties and do not leak wine. For example, if used with an aluminum foil-covered PE pad, its oxygen permeability and water permeability are lower.

And 3105 aluminum alloy bottle cap material is suitable for large-area precision printing, multi-color printing, side roll printing, etc. A variety of technologies can be applied, with large design space, easy color matching, good saturation, and high smoothness.

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ni | Ti | Other | Al | |

3105 | 0.6 | 0.7 | 0.3 | 0.3-0.8 | 0.2-0.8 | 0.2 | 0.4 | - | 0.1 | Each | Total | remain |

0.05 | 0.15 | |||||||||||

Alloy | Temper | Width (mm) | Sheet Length (mm) | Coil ID | ||

Thickness | Sheet | Strip | ||||

3105 | H14,H24,H16 ,H26,H18 | 0.16-0.28 | 500-1000 | 20-1000 | 500-1000 | 75 150 300 350 505 |

Quality control

Tolerance | |||

Thickness | Width | Length | Squareness |

±0.01mm; ±0.005mm is reachable | ±0.5mm | ±0.5mm | ≤0.5mm, ≤0.3mm if special request |

Edge Waviness ≤4 waves if the deviation from flat does not exceed 2mm. It is ≤3 waves if the deviation from flat does not exceed 3mm.

Appearance: Surface must be free from defects such as scratch, corrosion, dent , brown stain, stain line, residual oil film, pinhole, wrinkle, etc.

The main metal element of 3105 aluminum coil is Al-Mn. On the basis of 3003 aluminum alloy, some Cu and Mg are added to increase the mechanical properties of the finished product. 3105 aluminum sheet has higher strength than 3003 aluminum sheet including the compressive strength.

3104 aluminum sheet and 3105 aluminum sheet have a very high 99% of their average alloy composition in common.3104 is a variation of 3004 that was registered in 1978 to improve efficiency in can making.

3105 aluminum has excellent anti-rust properties, excellent electrical conductivity, and the electrical conductivity can reach 41%. The 3105 aluminum plate has high plasticity under quenching.

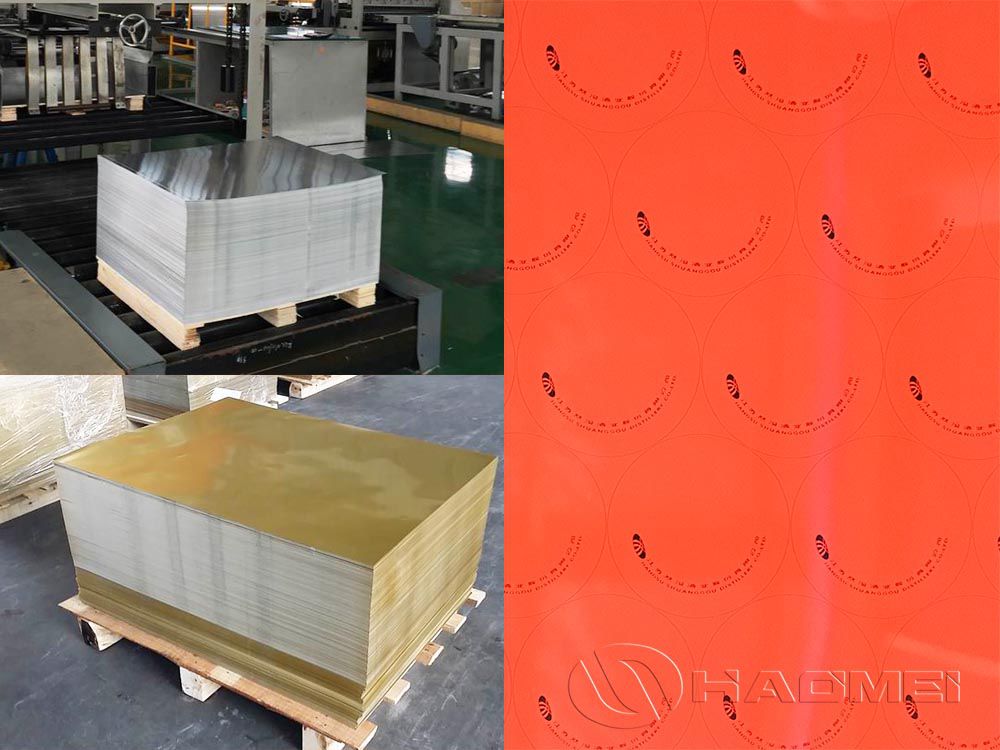

Haomei Aluminum owns an extra-long cleaning line and domestic flat shears to ensure that the surface of the product is clean and oil-free, and the ear-making rate is low. The aluminum sheet for bottle cap is widely used in bottle cap packaging for wine, beverages, medical caps, cosmetics, etc. The surface alkali cleaning can reach the A-level standard of brush water test. Our 3105 aluminum foil for bottle caps has been exported to more than 40 countries and regions such as South Korea, North America, Southeast Asia, and the United States.

Product

Application

Blog

+86-15978414719

+86-15978414719

sale@alumhm.com