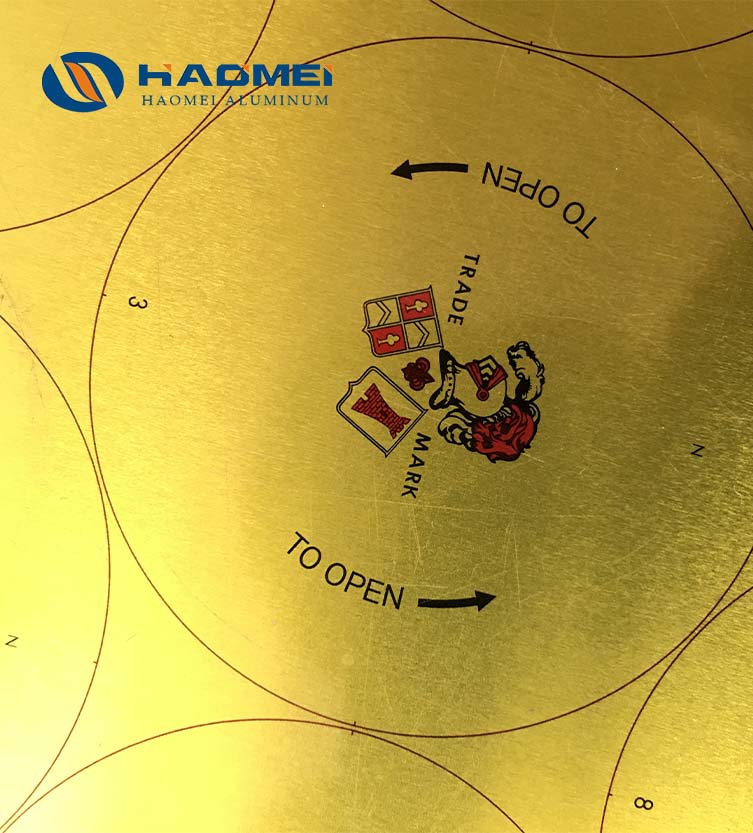

There are rich alloys of aluminum foil sheet for making bottle cap, including 8011, 1060, 3104, 3105, 5052 and 5182. Among them, 8011 aluminum foil is the most popular one. Its elongation rate is generally not less than 4 and it reaches water washing grade A. It it can meet special requirements such as high-temperature cooking and sterilization.

1060 aluminum foil is generally used for the making of aluminum plastic bottle caps. 3105 aluminum sheet has higher strength, which can be used the packaging of carbonated beverage. 5052 aluminum sheet is used for beverage caps and food caps without internal pressure, and 5182 alloy is used for beverage caps with internal pressure. All of our bottle cap material has SGS report.

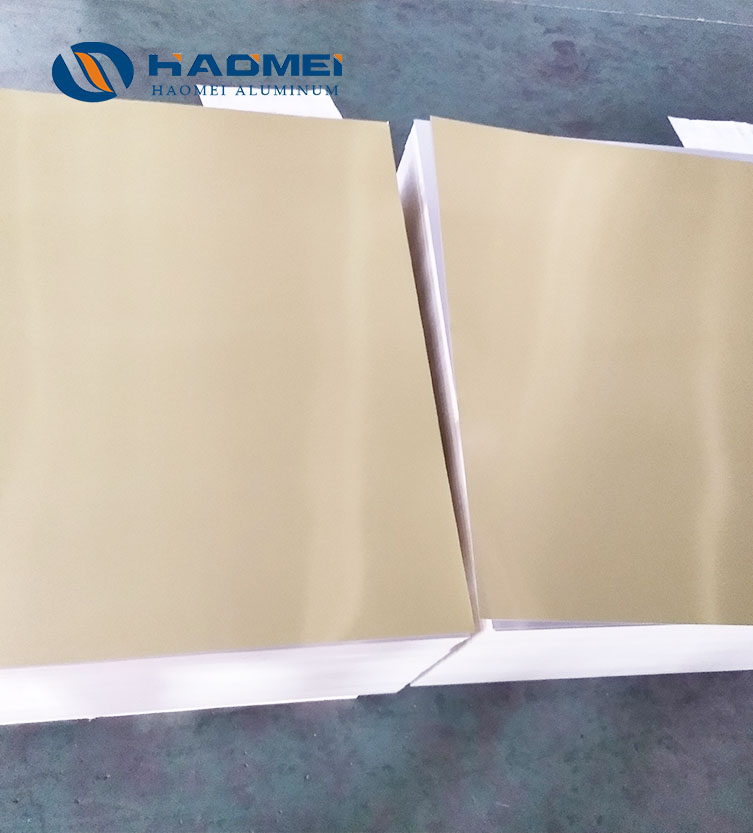

8011

The hardness of 8011 aluminum plate is between H14-H24. It is the most commonly used aluminum bottle cap material. Different surface treatments are available. Food grade, rich choices. Inquire now!

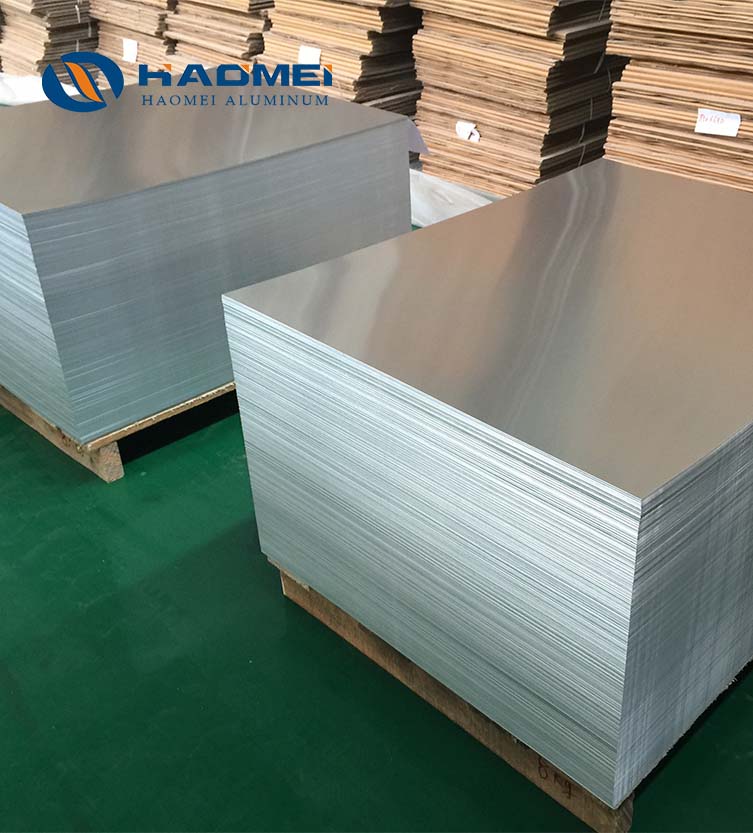

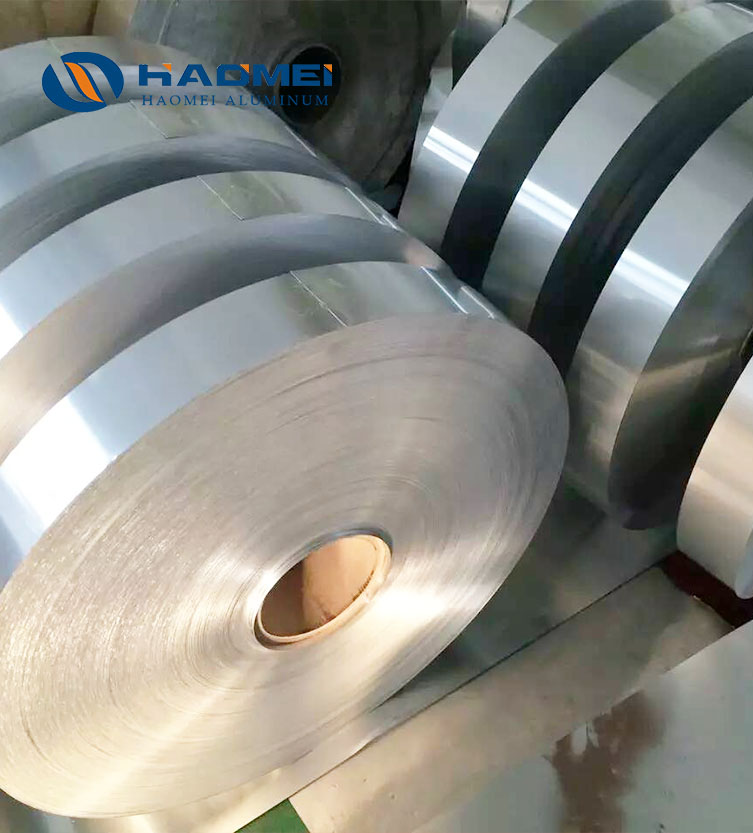

1060

Most of 1060 aluminum sheets are used for cosmetic bottle caps and some are for pharmaceutical bottle caps. It is usually used in the form of aluminum and plastic combination. Inquire now!

3104

3104 aluminum sheet is often used to make the body of the pop cans and can lids. It has high tensile strength and elongation,which is our best selling product. Inquire now!

3105

3105 aluminum foil sheet are widely used for making bottle caps of wine, beverage,medicines,especially the carbonated beverages due to high strength. Different surface treatments are available. Learn more.

5052

5052 pre cut aluminum foil sheets are used for beverage and food pop can lids like 202 can lid, 206 can lid and 209 can lid. We also provide 5182 aluminum sheet for pop cans. Inquire now!

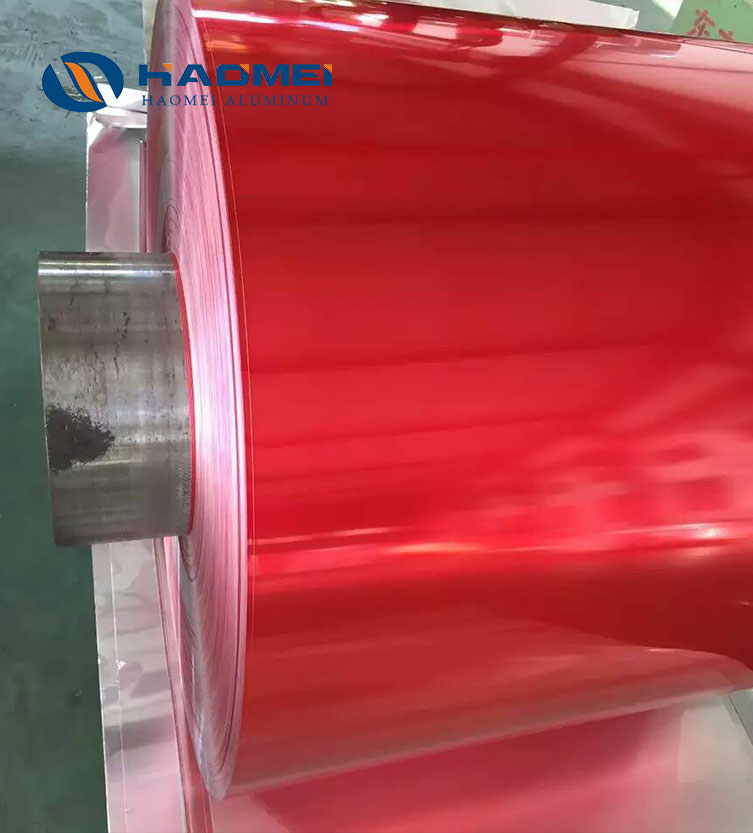

5182

5182 aluminum with high surface finish and medium strength is often used for the pull ring and can lid of the pop cans. It is applicable for 202, 206, 209 can lid. Best price, Inquire now!

+86-15978414719

+86-15978414719

sale@alumhm.com