The hardness of 8011 aluminum plate is between H14-H24. It is the most commonly used aluminum bottle cap material. Different surface treatments are available. Food grade, rich choices. Inquire now!

Alloy8011

TemperH14,H24,H16 ,H26,H18

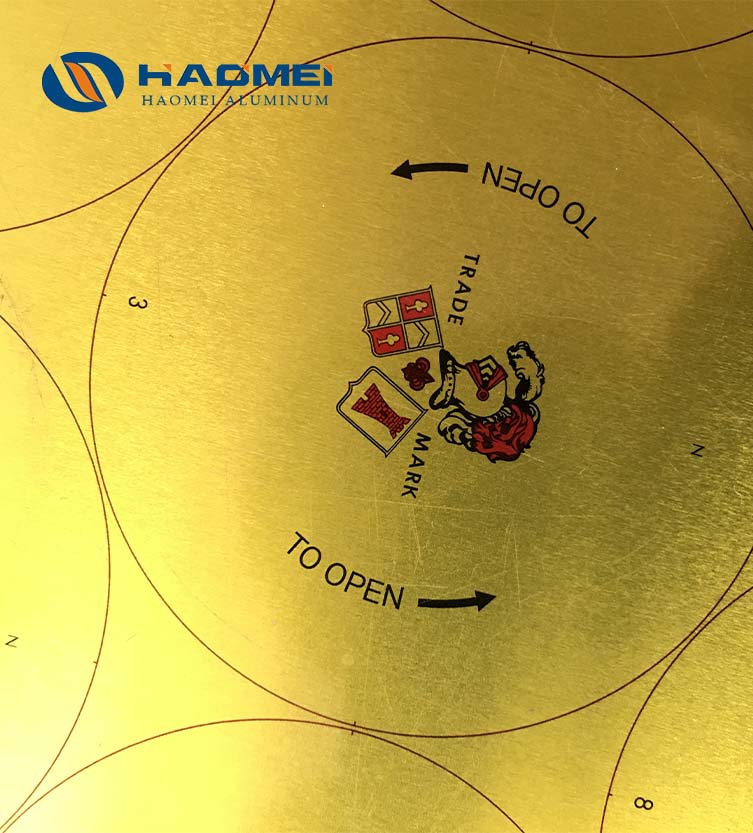

Surfacemill finish, coated, printed

Applicationwine bottle caps, beverage bottle caps, milk powder easy-to-tear lid,etc.

CERTIFICATE

8011 aluminum foil sheet has good tensile properties, ear-making rate and corrosion resistance. The surface is free of oil stains, dents, inclusions, scratches, stains, oxide discoloration, breaks, corrosion, and rolling marks. It is widely used to make different caps of different bottles like wine bottle, beverage bottle, milk powder easy-to-tear lid,etc.

The hardness of 8011 aluminum plate is between H14-H24, tensile strength is between 110-320, elongation is generally not less than 4, brush water is A grade and ear making rate is low, which can meet special requirements such as high-temperature cooking and sterilization.

Alloy | Temper | Thickness(mm) | Width(mm) | Sheet length(mm) | Coil ID | |

8011 | H14,H24,H16 ,H26,H18

| 0.16-0.28 | Sheet | Coil | 500-1000 | 75/ 150/300/ 350 505

|

500-1000 | 20-1000 | |||||

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ni | Ti | Other | Al | |

8011 | 0.50-0.9 | 0.60-1.0 | 0.10 | 0.20 | 0.05 | 0.05 | 0.10 | - | 0.08 | Each | Total | remainder |

0.05 | 0.15 | |||||||||||

8011 aluminum foil belongs to the 8 series aluminum alloy, in which Al-Fe-Si elements are added. With more than 1% of total alloy elements, its alloy properties have correspondingly higher advantages. 8011 aluminum foil has a wide range of uses, especially in the field of bottle cap materials.

In addition to deep stamping performance and low ear-making rate, 8011 aluminum foil sheet has a certain strength after process hardening, making it more in line with the requirements of bottle cap materials.

8011-H18 aluminum bottle cap material is mainly used in stamping shallow caps; 8011H16 bottle cap aluminum material is an important member of hot-rolled aluminum anti-theft cap materials. There are still slight differences in the production process between 8011-H16 medical bottle cap materials and wine cap materials. Since wine caps have higher stretching requirements than pharmaceutical caps, there are differences in annealing.

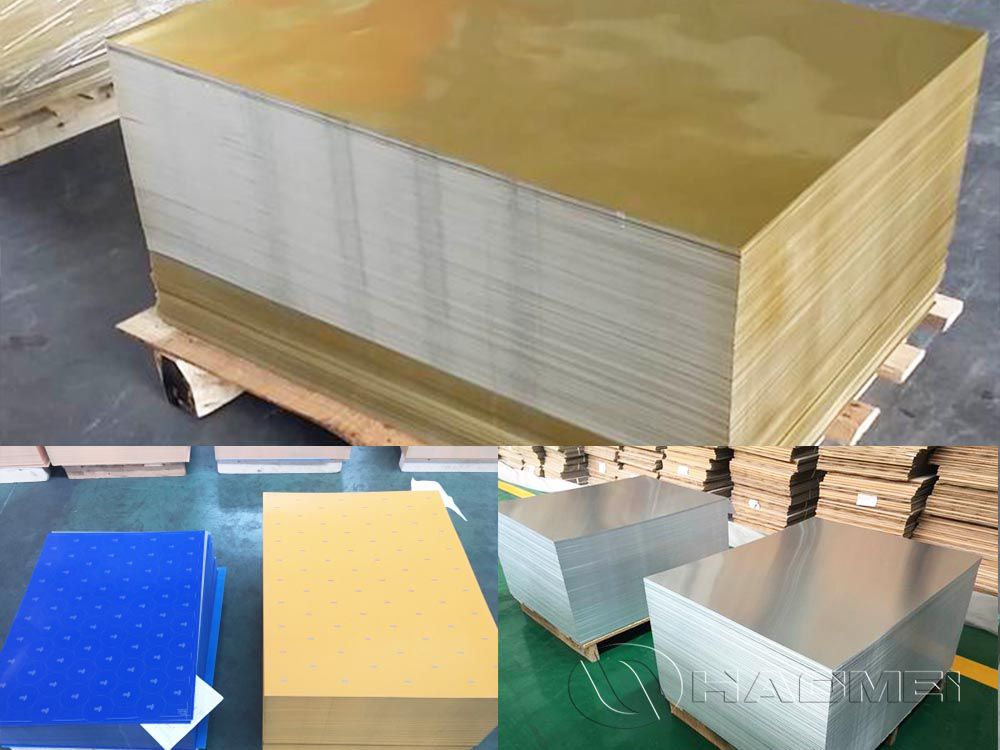

The 8011 aluminum alloy undergoes smelting-casing-hot continuous rolling-cold rolling-intermediate annealing-cold rolling-tension straightening-slitting or transverse cutting---packaging, and finally the aluminum alloy is formed.

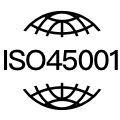

1. Plain Aluminum sheet: We have a strict control of the raw material like DOS oil. The chosen DOS oil has SGS report.

2. Pre-coated aluminum sheet: BPA free.

3. Color printed aluminum sheet: It can be printed with rich patterns, logos and words to improve product appearance.

Tolerance | |||

Thickness | Width | Length | Squareness |

±0.01mm; ±0.005mm is reachable | ±0.5mm | ±0.5mm | ≤0.5mm, ≤0.3mm if special request |

Edge Waviness ≤4 waves if the deviation from flat does not exceed 2mm. It is ≤3 waves if the deviation from flat does not exceed 3mm.

Appearance: Surface must be free from defects such as scratch, corrosion, dent , brown stain, stain line, residual oil film, pinhole, wrinkle, etc.

1. We have the "1+4" hot rolling production line with a high production capacity of 450,000 tons.

2. The plate convexity is well controlled.

3. It can meet various processing requirements of users and is suitable for multi-color printing.

4. It has strong sealing performance, relatively low cost, no pollution, and can be effectively recycled. It can well meet the requirements of high-temperature cooking and sterilization of wine, beverages and other products.

5. The surface alkali cleaning can reach the A-level standard of brush water test.

6. It is of precise geometric dimensions and the surface gloss is also high.

Product

Application

Blog

+86-15978414719

+86-15978414719

sale@alumhm.com