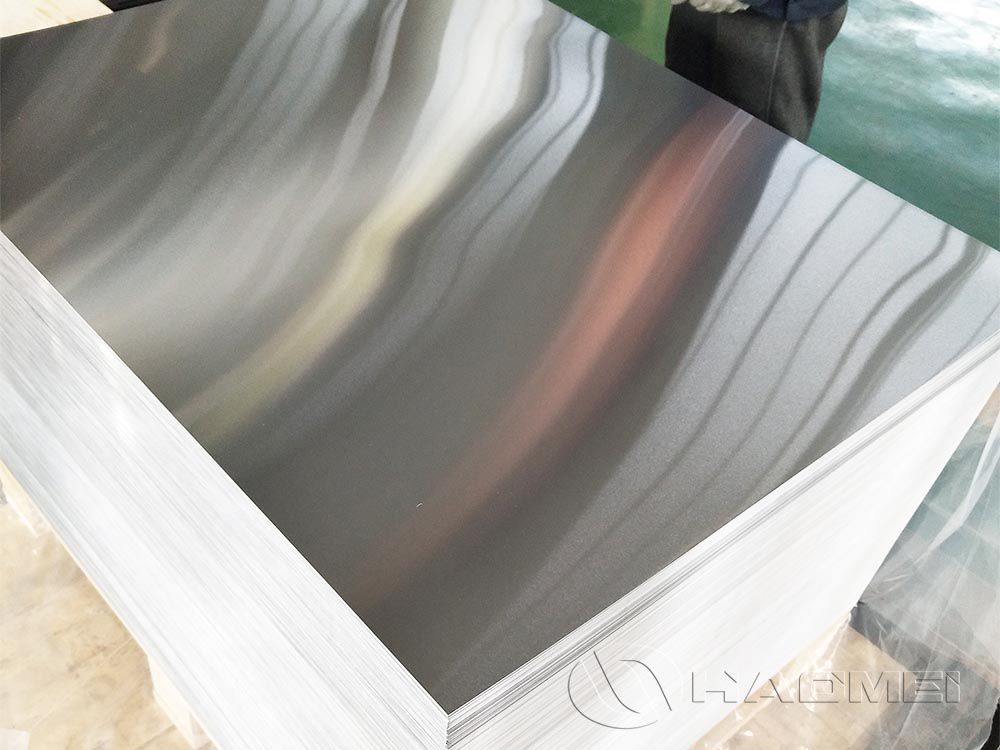

Aluminum bottle cap plays an important role in the safety and stability of the drug. Haomei Aluminum can provide plain/coated/printed aluminum sheet/coil for making medicine bottle caps. Learn more.

CERTIFICATE

The quality of pharmaceutical bottle caps is directly related to the sealing of the entire package, and plays an important role in the safety and stability of the drug during its validity period. According to the sealing principle of aluminum bottle caps, they can be divided into flat pressure sealing and side wall sealing.

Flat pressure sealing can only be used in screw caps. When tightened, the contact surface of the sealing ring between the plane of the bottle mouth and the inner plane of the bottle cap increases, thereby achieving a sealing effect. Side wall sealing uses effective contact between the bottle mouth and the outside of the cap sealing system to achieve a sealing effect.

For injections, the glass cover is often a metal cap combined with a rubber stopper, which requires design selection based on the structure and use of the product as well as price.

1060 aluminum sheet adopts a cap-making method that combines aluminum and plastic. Since the aluminum-plastic bonded part will come into contact with the liquid in the bottle, most of it is used in the cosmetics industry, and some are also used in the pharmaceutical industry. 8011 aluminum foil generally adopts a capping method of direct stamping. Compared with the two alloys, 8011 has better performance.

The pharmaceutical and healthcare industry has shown continued strong growth rates, with demand surging in several regions including North America, Europe and Asia Pacific. Aluminum caps and closures used in the pharmaceutical industry are sterile and often consist of layered materials. Furthermore, aluminum can be highly customized: natural or colored, plain or embossed.

Haomei Aluminum can provide plain/coated/printed aluminum sheet/coil for making medicine bottle caps. We can fully meet the requirements of the downstream pharmaceutical bottle cap manufacturers.

Additionally, aluminum caps create a highly effective barrier without compromising product taste and odor. Aluminum caps are completely neutral and help prevent flavor, color and other changes that occur in medications. As the global diabetes population increases, so does the use of insulin injections, syringes, and pens. This further drives the use of aluminum caps for syringe nozzles, vials and other cartridges

Furthermore, the pharmaceutical industry is growing exponentially with the increasing demand for over-the-counter (OTC) drugs. For example, according to IQVIA's research report, the over-the-counter drug market is growing at a global rate of 3-6%. As most of the aluminum caps and closures are used in the OTC market, this is expected to further drive its demand in the global range.

Product

Alloy

Blog

+86-15978414719

+86-15978414719

sale@alumhm.com