The sealing performance of cosmetics has an important impact on the shelf life of cosmetics. The pre painted aluminum coil helps improve the cosmetics’ appearance. Learn more.

CERTIFICATE

Aluminum and its alloys have become the second largest category of metal materials used in the world after steel due to their high strength/weight ratio, easy processing and forming, and excellent chemical and physical properties.

The aluminum alloy for cosmetic bottle caps can achieve a mirror effect, rich color, metallic feel and strong stain resistance after stamping, stretching, mechanical polishing, electrolytic polishing and anodizing coloring, and is gradually accepted by the market.

The sealing performance of cosmetics has an important impact on the shelf life of cosmetics. The sealing effect of cosmetic aluminum bottle caps is good with 1060 aluminum foil. At present, cosmetic bottle caps on the market mostly use plastic materials and aluminum-plastic composite materials. In comparison, aluminum-plastic composite materials have better sealing performance and more beautiful appearance.

It is a bottle cap material chosen by many high-end cosmetics. The aluminum-plastic bonded part of the aluminum-plastic composite bottle cap material will come into contact with the liquid in the bottle, so 1060 aluminum foil is often used as the aluminum foil bottle cap material.

Aluminum alloy cosmetic bottle cap materials are mostly processed on production lines with a high degree of automation. Therefore, the strength, elongation and dimensional deviation of 1060 aluminum foil are very strict, otherwise cracks or creases will occur during processing. 1060 aluminum foil has the characteristics of high plasticity, corrosion resistance, electrical conductivity and thermal conductivity.

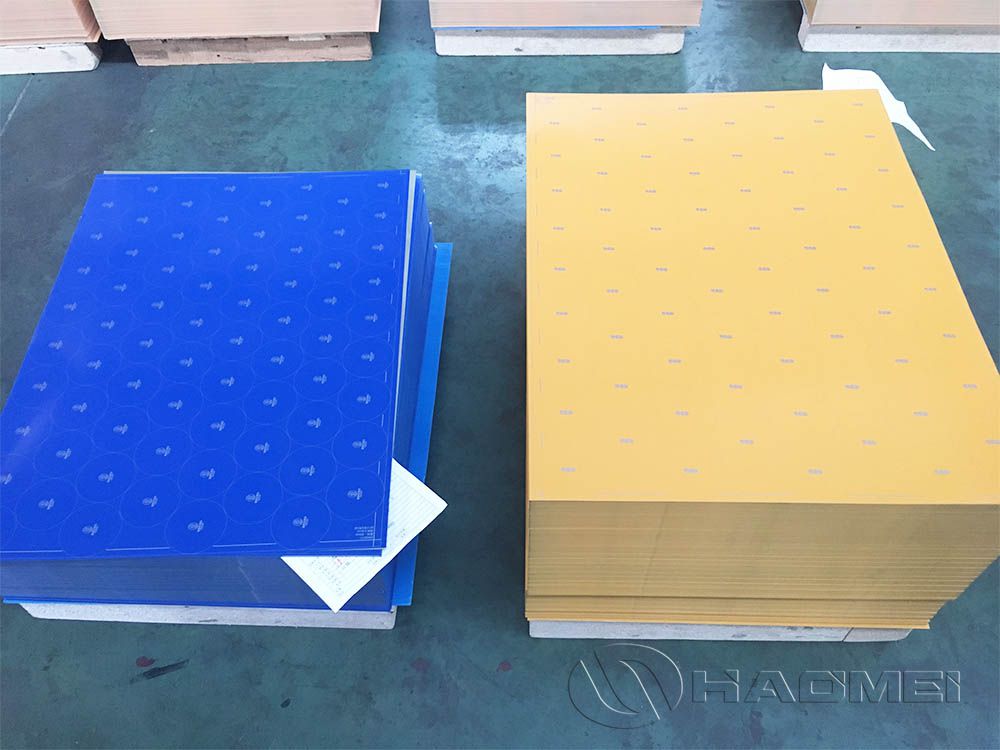

3104 pre painted aluminum coil is a deformed aluminum alloy with the characteristics of corrosion resistance, high tensile strength, good formability and excellent elongation. It is suitable for deep drawing to reduce the amount of material.

5052 aluminum coil is an Al-Mg alloy with good corrosion resistance, excellent weldability, good cold workability, and medium strength. It is widely used in bottle cap materials, food container,etc.

8011 aluminum foil has the advantages of clean surface oil removal, low ear-making rate, high cup convex value, high strength, and good sealing. The 8011 aluminum foil is widely used in wine, beverages, medical caps, cosmetics, etc.

Product

Alloy

Blog

+86-15978414719

+86-15978414719

sale@alumhm.com