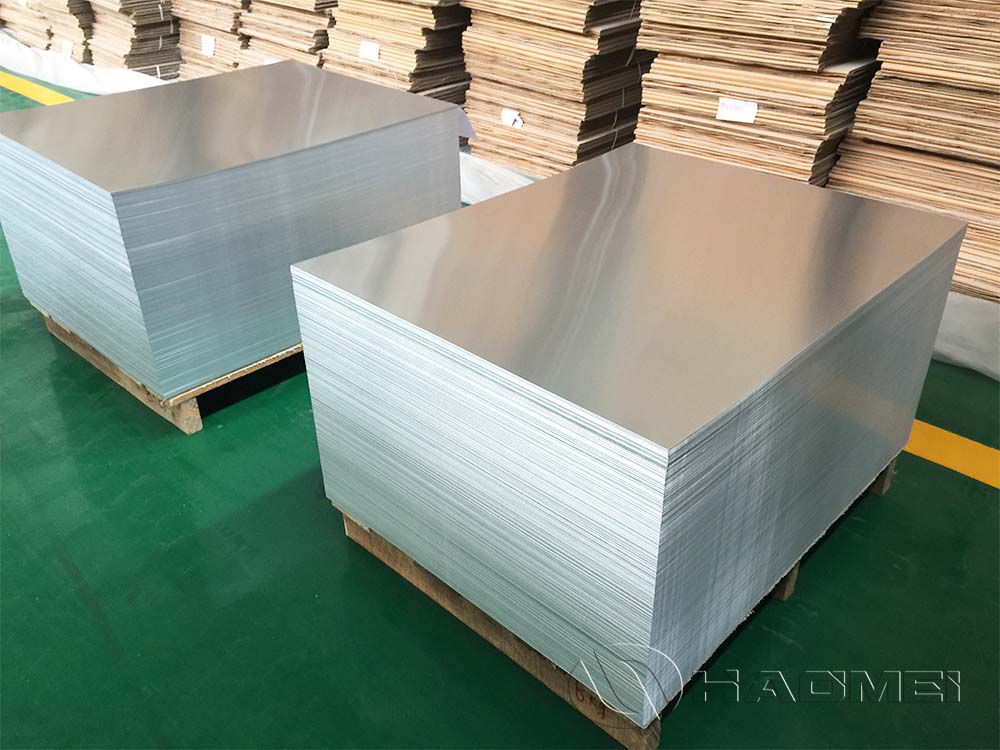

5052 pre cut aluminum foil sheets are used for beverage and food pop can lids like 202 can lid, 206 can lid and 209 can lid. We also provide 5182 aluminum sheet for pop cans. Inquire now!

Alloy5052

TemperH19

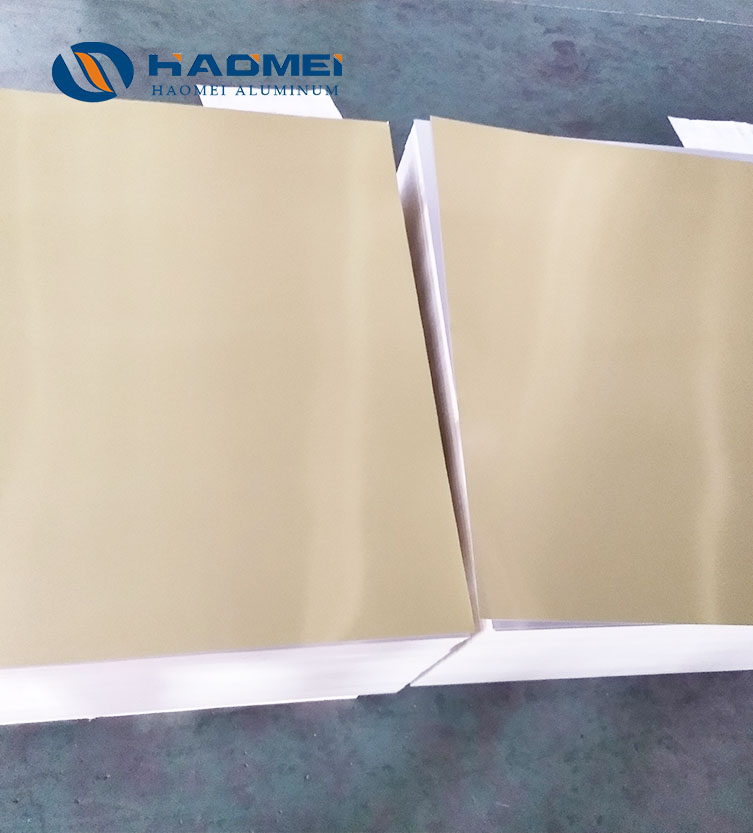

Surfacemill finish, coated, printed

Application202 can lid, 206 can lid, 209 can lid

CERTIFICATE

As people's quality of life improves and eating habits change, beverages packaged in aluminum cans are also increasing rapidly. The number of cans used for beer, carbonated drinks, tea drinks, energy drinks, etc. is growing rapidly. Hundreds of billions of cans are consumed globally every year, and the number is still increasing.

Aluminum alloys are widely used in the metal packaging industry because they are easy to process, moisture-proof and corrosion-resistant, light in weight, environmentally friendly and recyclable, and non-toxic.

5052 and 5182 aluminum alloys are used for the can lids. 5052 alloy has a low magnesium content while the 5182 alloy is an alloy with a high magnesium content. In terms of manufacturing easy-open lids, 5052 alloy is used more, accounting for about 60% of the total, and the thickness is mostly 0.22-0.26mm.

5052 pre cut aluminum foil sheets are used for beverage caps and food caps without internal pressure, and 5182 is used for beverage caps with internal pressure. At present, the production process of 5052 aluminum alloy can lid is: casting → sawing → milling → homogenization annealing → hot rolling → 1 pass of cold rolling → 2 passes of cold rolling → 3 passes of cold rolling → cold rolling 4 passes→5 passes of cold rolling→annealing→stretch bending→coating→finished product shearing.

Product | Alloy | Temper | Thickness(mm) | Width(mm) | ID(mm) | Application |

Can lid | 5052 | H19 | 0.218-0.35 | 200-1950 | 405 505 | 202 can lid 206 can lid 209 can lid |

Tensile strength: 270-330 Mpa

Yield strength: 240-300 Mpa

Elongation: ≧5

Thickness: 0.208-0.360 mm

Thickness tolerance: ±0.005

Width: 800-1730 mm

Width tolerance: +1.0

Haomei Aluminum’s 5052 aluminum foil for bottle cap can achieve a flat shape and extremely precise thickness control, ensuring a thickness tolerance of ±0.005mm, ensuring stable post-processing, and fully meeting customer needs.

1. the aluminum sheet oes not allow obvious waves, the wave height within 1 meter does not exceed 3mm, and the waves do not exceed 3/meter;

2. the side curvature on any 2000mm length should not be greater than 0.5mm;

3. Within any length o 1500 mm, the height of the end warp should be ≤5mm.

There are no serious bubbles, missed coatings, scratches, corrosion, oil spots, peeling, streaks, color differences, spots, roller marks, periodicity, etc. that affect the appearance quality of the product.

1. Aluminum alloy cans have the characteristics of good strength, corrosion resistance, and machinability. They have high surface finish and are very suitable for post-processing.

2. Aluminum cans have the advantages of light weight, heat resistance, good conductivity, odorless and non-toxic, and good printing effect. Welcome to leave message below to inquire aluminum plain sheet price.

Product

Application

Blog

+86-15978414719

+86-15978414719

sale@alumhm.com