The higher requirements are required for the sealing of some soda and other carbonated beverage. 3105 aluminum sheet with higher strength is an ideal choice. Inquire now!

Applicationbottle cap material

Alloy3105

CERTIFICATE

A bottle cap is a device used to close or seal a container such as a bottle, jug, jar, tube, or jar. The main types of bottle caps include: rotary bottle caps, crown bottle caps, flip-top bottle caps, cork stoppers, etc.

As the use of bottle caps continues to increase, ordinary bottle caps can be used to seal beverages without carbonated gas such as mineral water, tea, and juice. However, higher requirements are required for the sealing of some soda and other beverage containers containing carbonic acid gas.

In order to prevent the carbonic acid gas inside the container from leaking out quickly, the internal carbonic acid gas and the internal bottle pressure must be maintained. This requires the aluminum bottle cap material has a good sealing performance and a certain strength.

In the field of food and beverages with abundant products, bottle caps are a product that is easily overlooked by us.

Although the bottle cap is small, it plays an important role in food and beverages. It not only makes the product easier to carry and avoids direct contact with the outside air, but also acts as a "delicious guardian" in the field of "happy water" - making Carbonic acid gas has nowhere to escape!

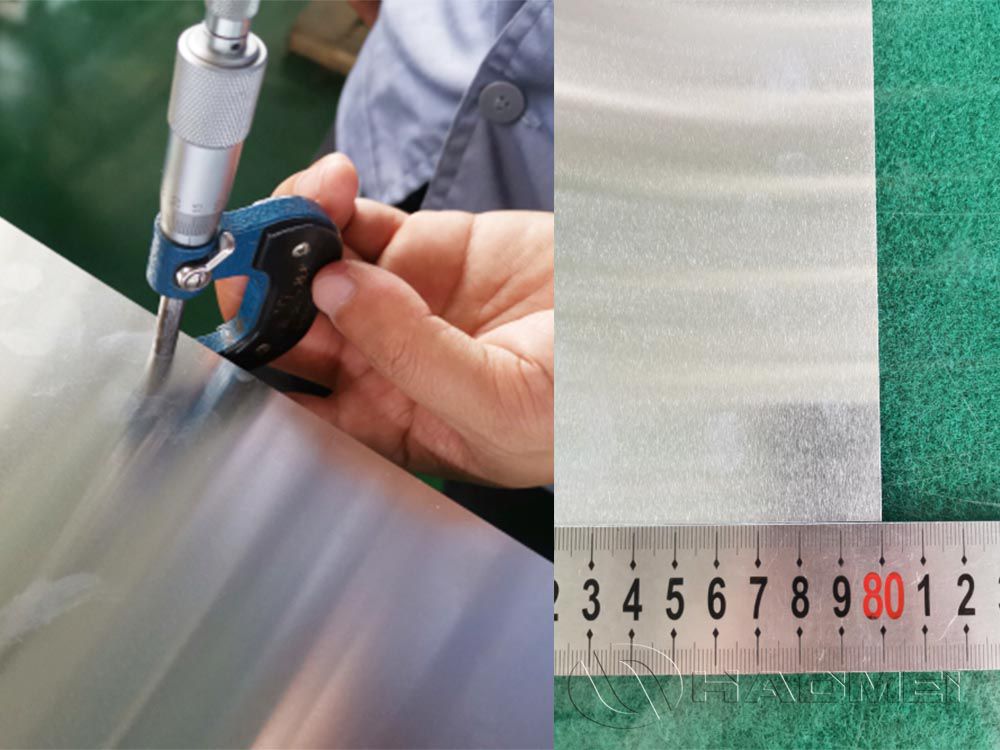

For carbonated beverage and sparkling drinks, 3105 aluminum sheet is an ideal choice. On the basis of 3003 aluminum alloy, some Cu and Mg are added to increase its mechanical properties. 3105 aluminum sheet has higher strength than 3003 aluminum sheet including the compressive strength. It has different types: aluminum plain sheet, aluminum coated sheet and printed aluminum.

Alloy | Temper | Thickness(mm) | Width(sheet)(mm) | Width(foil/coil)(mm) | Length(sheet)(mm) | Sleeve inner diameter |

3105 | H14,H24,H16, H26,H18 | 0.150-0.500 | 500-1500 | 50-1500 | 500-2000 | 75.0,150.0,200.0,300.0,350.0,405.0,505.0 |

There are no serious bubbles, missed coatings, scratches, corrosion, oil spots, peeling, streaks, color differences, spots, roller marks, periodicity, etc. that affect the appearance quality of the product.

Product

Alloy

Blog

+86-15978414719

+86-15978414719

sale@alumhm.com