2024-07-30

Aluminum PP/ROPP caps are made of high-quality aluminum alloys and finely processed. They can meet special requirements such as high-temperature steaming and sterilization, and have beautiful appearance. The alloy grades of aluminum foil for bottle cap are 8011, 1060, 3105 and 3104 aluminum foil.

3104 aluminum sheet is a deformed aluminum alloy with a tensile strength of 275 MPa or more and an elongation of up to 20%; it has excellent deep drawing performance, processing performance, welding performance and corrosion resistance. This aluminum alloy has low density, high strength, easy forming and recyclability, and is very suitable for manufacturing can lids and can body. It is suitable for thinning, stretching and lightweighting to reduce material usage.

Al: remainder

Si: ≤0.50

Fe: ≤0.7

Cu: ≤0.10

Mn: 0.9~1.5

Mg: ≤0.30

Cr: ≤0.1

3105 aluminum alloy has good corrosion resistance, especially for oxidizing media and salt water corrosion; 3105 aluminum alloy is easy to process and cut, and can be used to manufacture various complex parts; 3105 aluminum alloy has good welding performance and can be used for welding and riveting.

3105 aluminum alloy luminum alloy cannot be heat treated to improve its strength and hardness. The hardness of 3105 aluminum alloy is generally between 40~45HB. Its tensile strength is ≧150MPa, yield strength is ≧95MPa, elongation is ≥1.5%

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ni | Ti | Other | Al | |

3105 | 0.6 | 0.7 | 0.3 | 0.3-0.8 | 0.2-0.8 | 0.2 | 0.4 | - | 0.1 | Each | Total | remain |

0.05 | 0.15 | |||||||||||

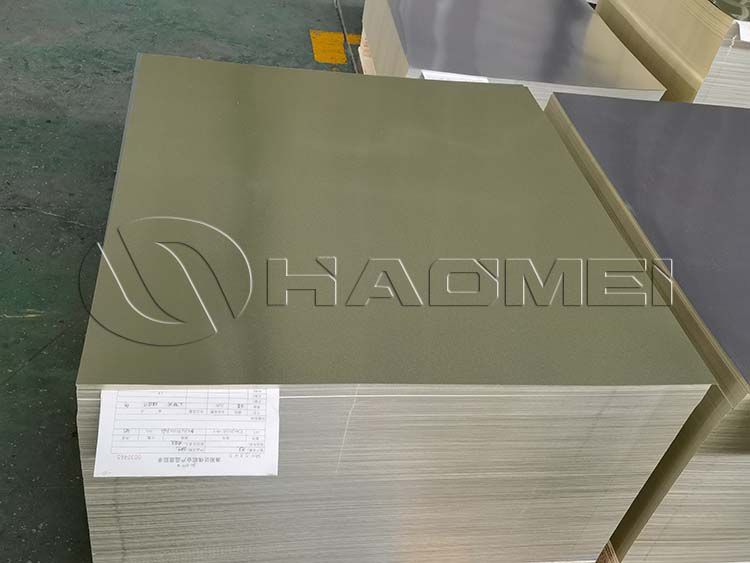

Haomei Aluminum has mastered the production process of 3105 aluminum alloy sheet using the continuous casting and rolling method, and has mastered the optimal matching range of key casting and rolling production process parameters such as the casting and rolling area, roll gap, opening degree, cooling water temperature, etc., so that the product quality and performance are stable.

The tensile strength of 3105-H24 aluminum sheet is the highest, reaching 176MPa, meeting customer requirements; the elongation reaches 17.5%, far exceeding the customer's requirement of ≥4%. In the H26 state, the strength of the 3105 alloy reaches about 200MPa, and the elongation is 8%-11.5%, both of which far exceed customer requirements. In addition, the product casting and rolling yield rate is ≥95.6%, and the comprehensive cold-rolled product yield rate is ≥90.4%.

Tags: aluminum foil for bottle cap |

Original Source: https://alclosuresheet.com/a/3104-and-3105-aluminum-foil-sheet-for-bottle-packaging.html

Product

Alloy

Application

+86-15978414719

+86-15978414719

sale@alumhm.com