2025-04-22

For the beer packaging, , the choice of beer bottle cap material directly affects product quality, transportation cost and environmental value. From traditional tinplate to modern aluminum alloy, the iteration of material technology is driving industry change.

Core advantages:

Tinplate has an ultra-thin design of 0.2-0.3mm and achieves near-perfect sealing through a double crimping process. Its corrosion resistance comes from the electrochemical protection of the tin layer on the steel, which is especially suitable for craft beer that is sensitive to oxygen.

Limitations:

Special tools are required to open the caps, and they are heavy (about 3.5g/piece), and the transportation cost is more than 15% higher than that of aluminum caps. In addition, the recycling rate of tinplate is only 60%, and high-temperature smelting is required, and the carbon emission intensity is 3 times that of aluminum.

Application scenarios:

PP (polypropylene) and PE (polyethylene) bottle caps are widely used in low-end and mid-range beer with their ultra-light weight of 0.8-1.2g and the flexibility of injection molding. Their threaded design supports bare-handed opening, which is suitable for outdoor consumption scenarios.

Technical bottlenecks:

Poor temperature resistance (PP bottle caps soften above 80°C), and plasticizers are easily released during long-term storage. The recycling rate is very low.

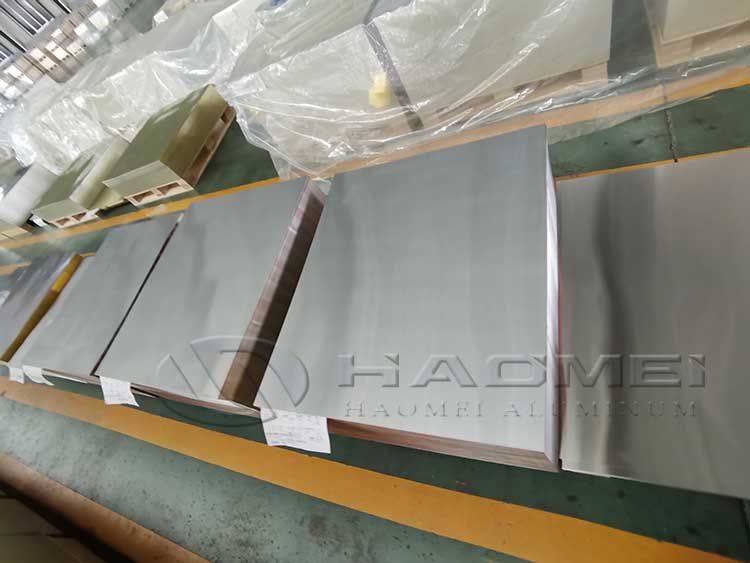

Aluminum bottle caps weigh only 1.5-2g, which is more than 50% lighter than tinplate. Its surface oxide film (thickness 2-3μm) can achieve corrosion resistance comparable to tinplate by anodizing or coating with food-grade coating.

Circular economy value:

The recycling rate of aluminum is as high as 71%, and the energy consumption of recycling is only 5% of that of original aluminum. EU data shows that the carbon footprint of aluminum bottle caps is 40% lower than that of plastics and 30% lower than that of tinplate.

1. Aluminum closure sheets can can achieve a production speed of 1,500 per minute through a multi-station stamping machine, which is 30% higher than the stamping efficiency of tinplate.

2. Aluminum sheet for bottle caps support different surface treatments like coating, printing, embossing, hot stamping, convex and flexographic printing, which can improve the bottle caps’ anti-counterfeiting performance and visual impact.

3. The PE or EPDM gasket on the inside of the aluminum cap forms a radial seal with the bottle mouth, while the serrated edge on the outside is curled by the capping machine to achieve axial sealing. This design keeps the headspace oxygen content of beer below 0.1ppm, which is much better than 0.3ppm of tinplate.

4. The carbon footprint of aluminum bottle caps from raw material mining to recycling is only 2.3kg CO₂/unit, while plastic bottle caps are 3.8kg and tinplate is 4.1kg. The EU's new regulations for 2025 require that packaging materials contain 35% recycled content, and the proportion of recycled aluminum in aluminum bottle caps has reached 50%.

Tags: bottle cap material |

Original Source: https://alclosuresheet.com/a/beer-bottle-cap-material-aluminum-closure-sheet.html

Product

Alloy

Application

+86-15978414719

+86-15978414719

sale@alumhm.com