2024-12-09

3000 aluminum alloys are not as strong as the 2000 series or 7000 series, but they strike a good balance between strength and flexibility. They can be easily formed and bent without breaking. 3105 coated aluminum sheet is a new type of bottle cap material which has been widely used in beverage bottles, wine bottles, cosmetic bottles, medicine bottles and other sealing packaging at home and abroad. 3105 aluminum alloy has all states such as O state, H12, H14, H18, H22, etc.

3105 aluminum is an aluminum-manganese alloy with good rust resistance, electrical conductivity and processing performance. It has excellent deep drawing effect, can meet the high automation strength of the bottle cap production process, and is not prone to creases or cracks during processing.

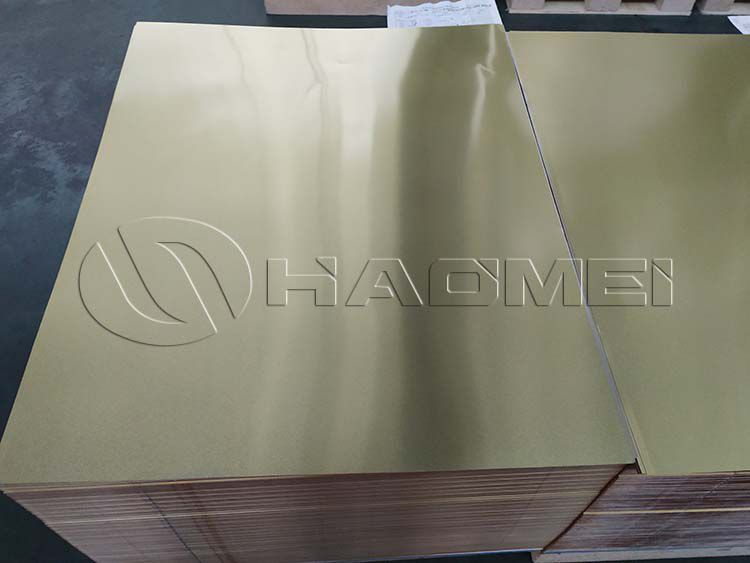

In addition, 3105 aluminum has high plasticity and strong adaptability in the annealed state. It can print colorful patterns, and the surface is flat without roller marks and oil spots, which is convenient for later printing and the pattern is clear and discernible. At the same time, its sealing performance is also very good, which can prevent the leakage of contents, and has excellent anti-counterfeiting performance, which can prevent the product from being counterfeited.

In the wine bottle cap manufacturing industry, 8011 aluminum foil is widely used due to its unique performance advantages. This aluminum foil not only has excellent physical and chemical properties, but also meets the high standards of safety and hygiene in the food packaging industry.

1. Excellent barrier properties

8011 aluminum foil has excellent barrier properties such as moisture resistance, oxidation resistance, and UV resistance. This feature is crucial to protecting wine products, and can effectively prevent the impact of the external environment on the quality of the wine, ensuring that the taste and quality of the wine remain stable for a long time. In addition, its high barrier capacity can also prevent the intrusion of oxygen and moisture, further extending the shelf life of the wine.

2. Good mechanical properties

8011 printed aluminum has excellent mechanical properties and is very suitable for stamping and forming bottle caps, which can ensure the stability and consistency of bottle caps during the manufacturing process. At the same time, strong mechanical properties also mean that the bottle caps can withstand certain external force impacts during use and are not easy to deform or break.

3. Good corrosion resistance

8011 aluminum foil for wine bottle caps has good corrosion resistance and is not easy to rust, ensuring the safety of wine during storage and transportation. Even in humid or harsh environments, aluminum foil bottle caps can maintain their original performance and appearance.

4. Clean surface, safe and hygienic

8011 aluminum sheet is clean and free of foreign matter, with uniform color and flatness. This feature makes it very suitable for food packaging, including wine bottle caps. During the production process, the aluminum foil undergoes strict degreasing and cleaning treatments to ensure the safety and hygiene of the product. At the same time, its non-toxic and odorless characteristics also meet the standard requirements for food packaging materials.

Tags: bottle cap material |

Original Source: https://alclosuresheet.com/a/3105-8011-aluminum-printed-sheets-for-bottle-cap.html

Product

Alloy

Application

+86-15978414719

+86-15978414719

sale@alumhm.com