2025-04-02

In the modern packaging industry, aluminum bottle caps have become an important packaging material for beverages, alcoholic beverages and daily chemical products due to their lightweight, strong sealing and recyclability. As its core raw material, aluminum sheet for bottle cap needs to meet strict performance requirements and testing standards.

The alloys of aluminum foil for bottle cap are usually 1100, 8011, 3105 and 3104. Among them, 1100 industrial pure aluminum (aluminum content ≥ 99%) is known for its high ductility, corrosion resistance, and conductivity, suitable for deep stamping processes, and widely used in ordinary bottle cap manufacturing; 8011 alloy optimizes the surface treatment effect while maintaining formability, and is often used in food packaging; 3104-H19 aluminum-manganese alloy has become the preferred material for can lids due to its high strength and uniform thickness.

Bottle cap production requires high-speed stamping, spinning and other processes, so aluminum plates need to have excellent ductility and fatigue resistance to avoid cracking or deformation during processing. For example, the tensile strength of 3104-H19 aluminum plate can reach more than 300MPa, and the elongation is controlled at 5%-8%, ensuring stable forming accuracy in automated production.

Bottle caps that come into direct contact with food or liquids need to be anodized or coated to improve acid and alkali resistance and avoid metal ion migration. Taking 1100 aluminum plate as an example, a dense oxide film is formed on the surface after anodizing, which not only enhances the anti-corrosion ability, but also achieves an aesthetic effect through coloring.

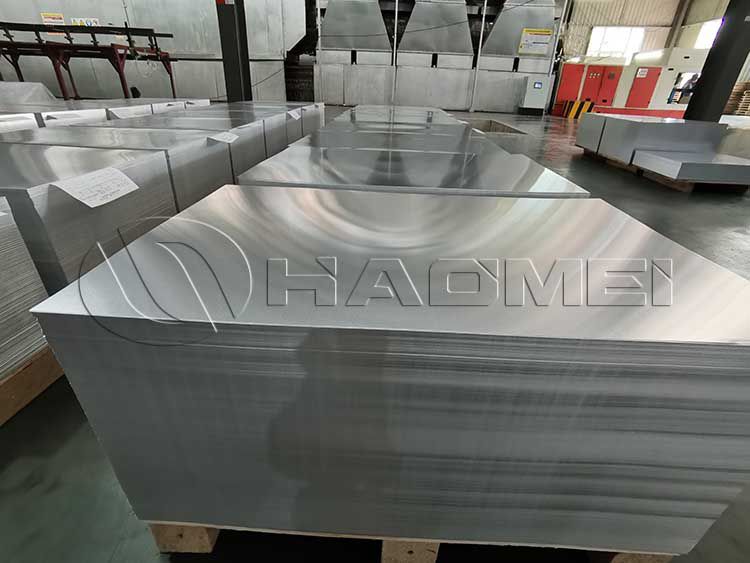

The surface of the aluminum plate must be free of scratches, oil stains, bubbles and other defects, and the thickness tolerance must be controlled within ±0.01mm. In addition, the dimensional stability test must ensure the flatness of the coil to avoid stamping deviation due to uneven stress.

The strength and ductility of bottle cap materials must be comply with major international standards. For example, the yield strength of 3104-H19 aluminum sheet must reach more than 270MPa to withstand the internal pressure during the canning process.

Haomei Aluminum will also simulate actual usage scenarios to test the torque, sealing and opening comfort of bottle caps made from our aluminum closure sheet. For anti-counterfeiting bottle caps, the reliability of special processes such as laser etching and coating adhesion must also be evaluated.

Tags: aluminum foil for bottle cap |

Original Source: https://alclosuresheet.com/a/aluminum-closure-sheet-for-bottle-cap.html

Product

Alloy

Application

+86-15978414719

+86-15978414719

sale@alumhm.com