2024-04-15

All-aluminum cans, also known as two-piece cans, are composed of a can body and a can lid, which are manufactured on different production lines using different aluminum alloys. The can body is made of 3004 painted aluminum coil with a thickness of 0.25mm-0.29mm, the beverage can lid is made of 5052 or 5182aluminum coil.

Due to the particularity of the aluminum alloy coil used for cans, the production process of hot rolling blank supply must be adopted. During the hot rolling process, the metallurgical structure, mechanical properties, surface quality, geometric dimensions, plate shape, etc. of the alumium coil must be reasonably controlled to meet the quality requirements of subsequent processing and final products.

5052 pre painted aluminum is mainly used in the bottle caps of cans. The 5 series alloy is added with magnesium, and its hardness is relatively better than other alloys. When it is used on cans, it can effectively solve the deformation caused by the impact of cans during transportation and ensure the beautiful appearance. Magnesium is the main alloy element in 5052 aluminum plate and is the most widely used anti-rust aluminum.

5182 aluminum alloy is mainly the main alloy for ring pull materials. With the development of the beverage industry and the replacement of old packaging materials, 5182 aluminum alloy will usher in greater applications in the packaging market. At the same time, 5182, as a high magnesium alloy, is a non-heat treatable alloy with good strength, corrosion resistance, and good machinability.

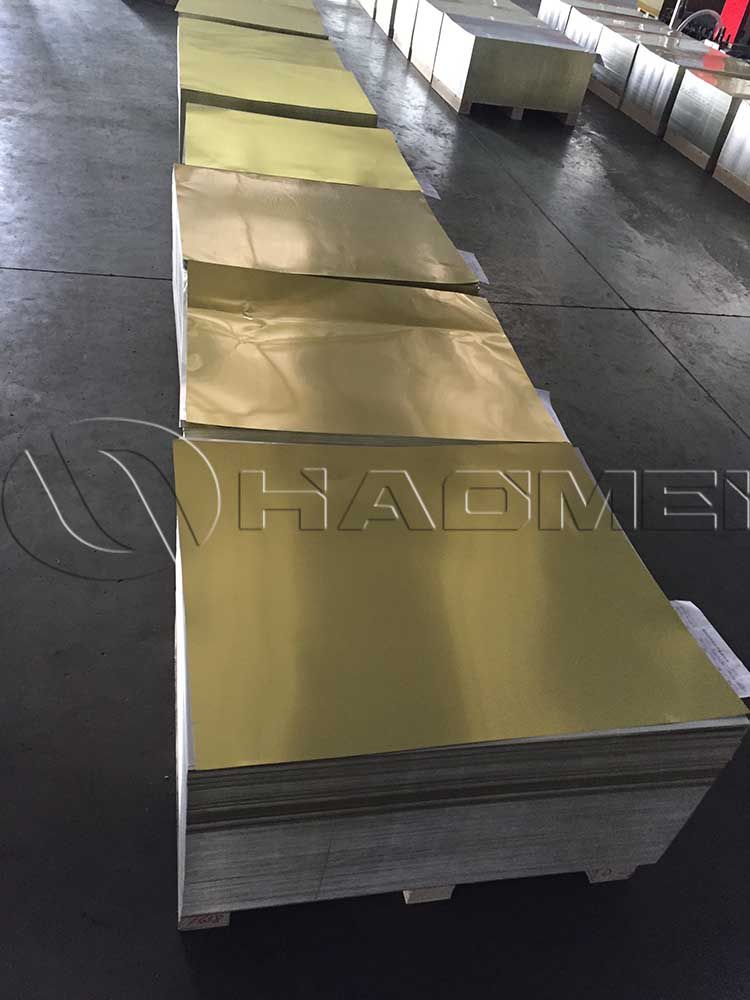

The pre painted aluminum coil for food packaging mainly involves pre-coating or pre-coating DOS oil on the aluminum base material, mainly using sheet coating and roller coating processes. Sheet coating refers to DOS pre-treatment first, and then cross-shearing and slitting. Roller coating refers to roller coating directly on the surface of the aluminum base material after cleaning without DOS treatment. It can be used directly or after cross-shearing and slitting. At present, from the perspective of technical process adaptability and large-scale production, roller coating has obvious advantages in the production of color-coated aluminum.

Haomei Aluminum’s aluminum painted coil adopts food grade paint. Food-grade environmentally friendly paint strictly follows relevant laws, regulations and standards in terms of ingredients. It usually uses harmless, low-volatile organic solvents and does not contain harmful substances such as formaldehyde, heavy metals, benzene, etc. It has passed a number of quality and safety certifications, such as European REACH regulations, US FDA certification, Chinese GB 4806.1 standards, etc., ensuring its safety for human health.

Tags: painted aluminum coil |

Original Source: https://alclosuresheet.com/a/painted-aluminum-coil-for-beverage-cans.html

Product

Alloy

Application

+86-15978414719

+86-15978414719

sale@alumhm.com